The textile industry is one of the oldest and most important branches of manufacturing in the world. Although the clothing industry has shifted mainly to the Far Eastern market, the production of technical textiles is even growing in Europe. With automated and continuous lubrication with simalube, unexpected machine failures can be reduced and costs saved.

| Challenges | Solution |

|---|---|

| High demands on the cleanliness of the equipment and its surroundings | Simalube with protection against vibration, often installed remotely |

| Often strong vibrations and oscillations |

Areas of application and advantages

| Typical installations | Typical applications | Further benefits |

|---|---|---|

| Processing machines | Bearings | Reliable lubrication with low maintenance requirements |

| Chains | Minimization of wear even at very high loads, thus reducing maintenance costs | |

| Guides | Cost savings thanks to significant reduction in maintenance requirements | |

| Gears |

Sold millions of times and suitable for any single point lubrication task with grease or oil.

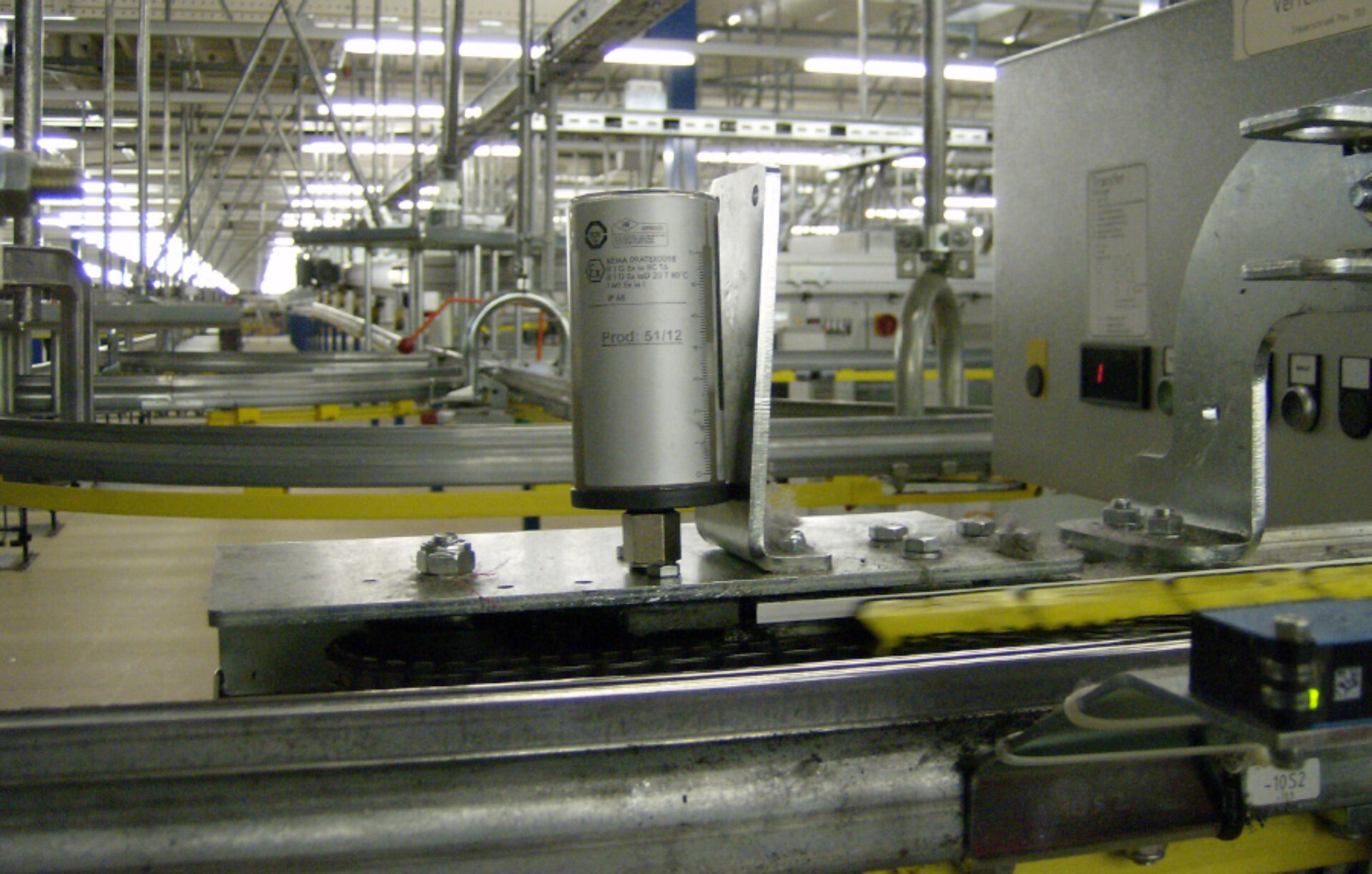

The automatic lubricator simalube provides all possible kinds of lubrication points with lubricant. 24 hours, day in, day out.

Roller bearings which are not lubricated sufficiently or wrongly drop out long before they have reached their expected product life. Simalube lubricators guarantee a consistent supply of lubricant in the pre-adjusted proportioning. Shutdown times are decreased and costs in comparison to time-consuming lubrication by hand are clearly reduced

Within seconds simalube is fixed to the lubricating point. On commissioning, a gas production cell is activated which presses the lubricant on the lubrication point through the release of hydrogen gas. The lubrication amount can be steplessly adjusted by means of an Allen key.

Filled with oil, Simalube is applied for the automatic lubrication of chains, open gears or guide rails for example.

Discover our fully automatic lubrication solutions at Pomac Lub-Services or browse the ILC range